We don't leave quality to chance

Good quality of course starts with the construction of the tool. Only when our tools are manufactured to be absolutely precise and true, will our parts exactly match customer specifications.

Regular product monitoring

In order to ensure that no mechanically-caused deviations sneak into production, we regularly sample the products and check them for tool specifications.

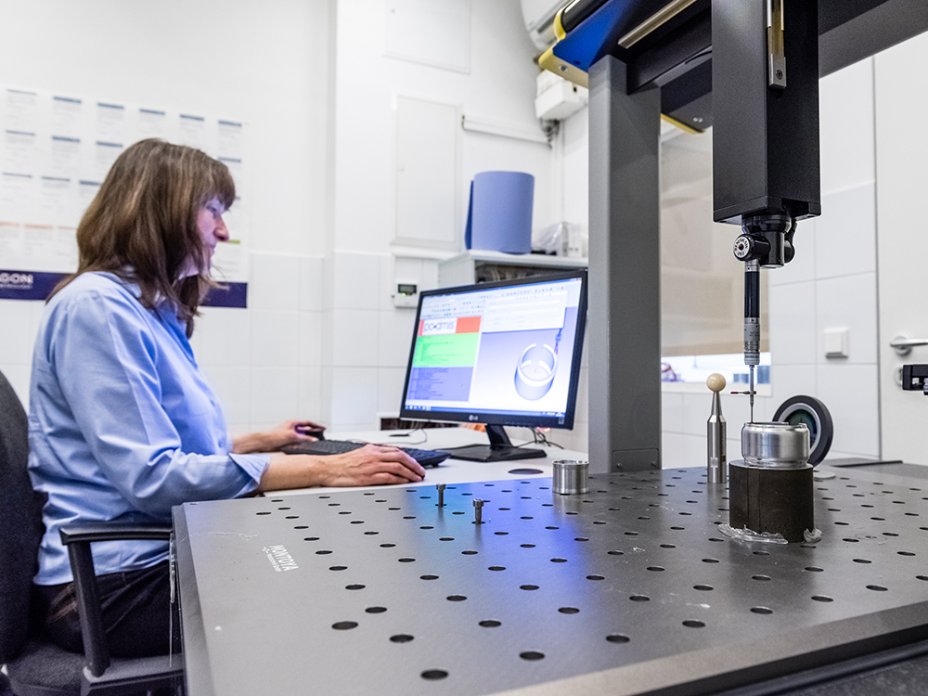

Most modern of testing technologies

We maintain our own test rigs and carry out a variety of testing procedures to ensure precise quality controls, e.g. for the testing of prototypes or our tools. In this way we can, for example, use 3D scanning methods to measure and monitor the surface structure of a component in a precise manner. This enables us to safely ensure that our products accurately meet the requirements of customer prior to series production and in each set-up process.